Get complete visibility of machine errors to expose line balance optimisation issues.

Software that helps you identify machine errors on your SMT production line and drill down to the root cause.

BoostSMT has made our SMT process much more efficient, much easier to work with and simpler for people to view issues and problems. Our defects have been greatly reduced. Overall its products have enhanced our manufacturing process. Without BoostSMT our process would be much more complicated and we would need more labour. Ultimately we’re able to output more product and bring in more customers.

Bill Riederer

Automation System Manager

Ultratec Inc

Overall SMT software gives us better visibility of our operations. We are able to identify errors quickly allowing us to meet OPRs and reduce waste – ultimately improving line balance and increasing throughput.”

Ross Clunie

Production Support Engineer

Gallagher

We encourage all our customers to use BoostSMT Analytics and BoostSMT Dashboard. The customisation and optimisation benefits are significant. The software helps increase yields, productivity and quality, as well as reduce component wastage and costs. It improves our machines’ operational efficiency and our customer satisfaction.

Robert Jung

CyberOptics

BoostSMT Analytics and BoostSMT Dashboard are powerful tools that give our customers a clear understanding of what’s happening on their production line, enabling them to drill down and make informed cost-effective decisions. BoostSMT’s software collects, analyses, and presents data clearly and visually, which is easy to interpret.

Richard Mitchell

Product Manager, Factory Software

Universal Instruments

BoostSMT Analytics and BoostSMT Dashboard are powerful tools that give our customers a clear understanding of what’s happening on their production line, enabling them to drill down and make informed cost-effective decisions. BoostSMT’s software collects, analyses, and presents data clearly and visually, which is easy to interpret.

Richard Mitchell

Product Manager, Factory Software

Universal Instruments

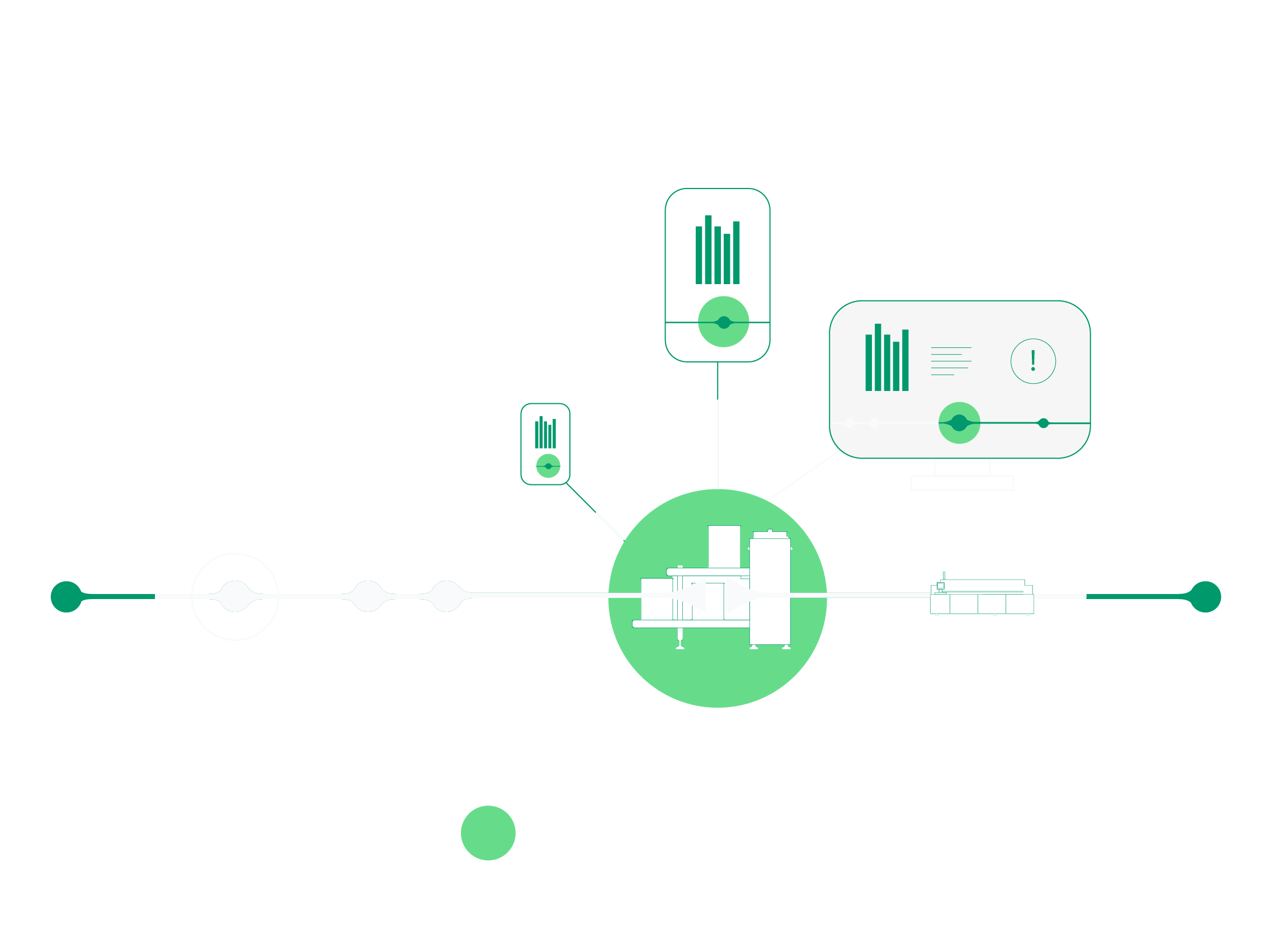

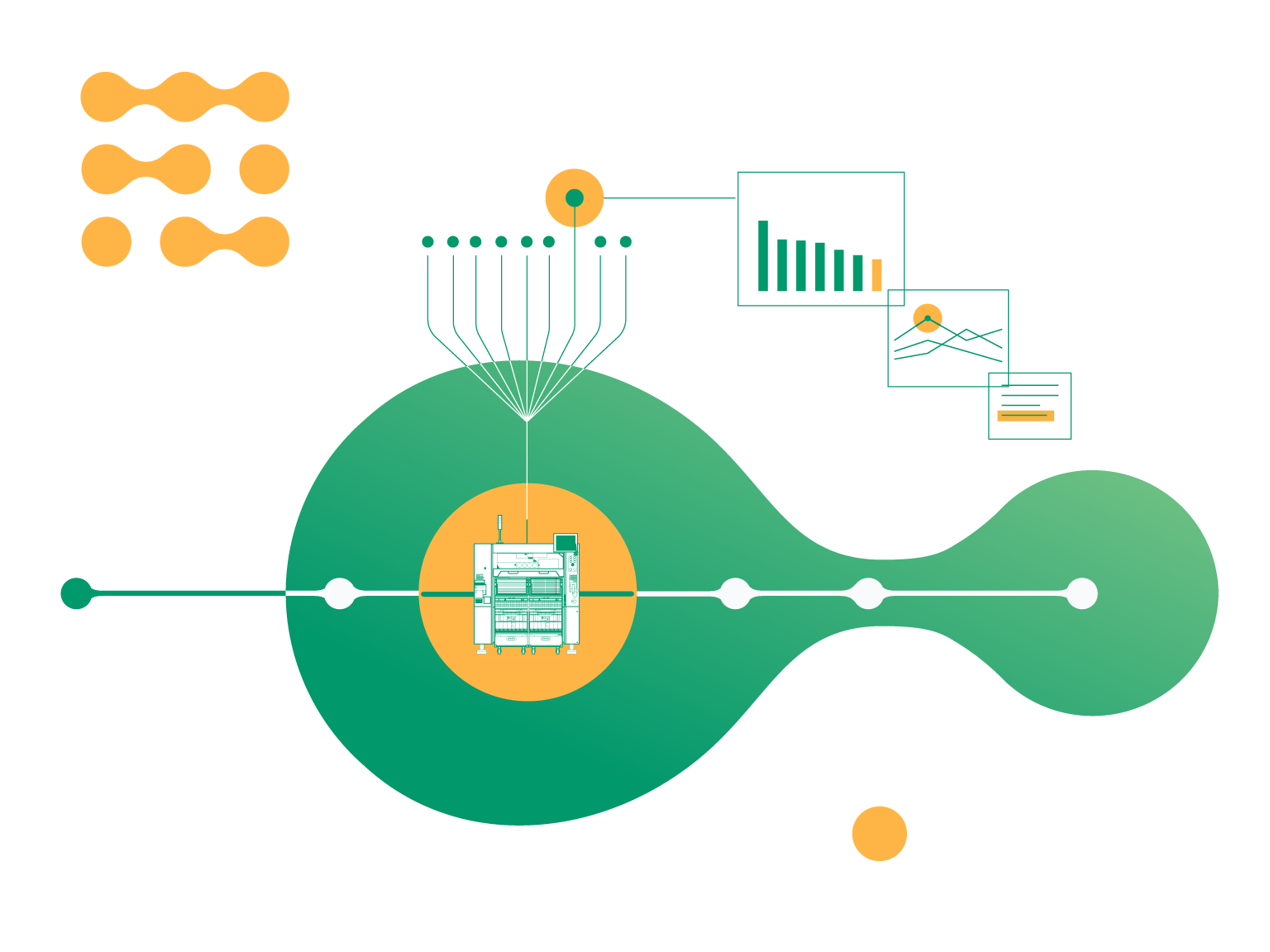

Visibility of your surface mount technology process where you need it most

Our industry 4.0 software makes it possible for different SMT and Inspection machine systems to combine with each other to produce cohesive, coherent data across production lines.

Giving you complete visibility of your SMT production line set-up, to easily identify errors, including:

● A faulty feeder that is not presenting to a machine properly – hindering output.

● Reduced algorithm performance that is dropping outside of the tolerance window.

● Where wastage is occurring.

Ultimately resulting in the ability to calculate assembly-line efficiency, improve throughput and maximize your SMT line production capabilities.

Our Production Line Software

We have two core, scalable products that work with both contract and OEM SMT production line applications.

BoostSMT

Dashboard

A real-time view of smt production line performance.

This piece of software provides an accurate machine status dashboard that gives you oversight on how the machines in a line are performing in real-time. This allows you to predict issues before they become problems.

BoostSMT

Analytics

Capture key data to identify errors on an smt production line.

This software enables you to calculate assembly line efficiency by delivering comparable data you can use to find where errors are occurring on your SMT production line.

SMS Linechart Products support these PCB, AOI and SMT brands:

Case Studies

BoostSMT Customers